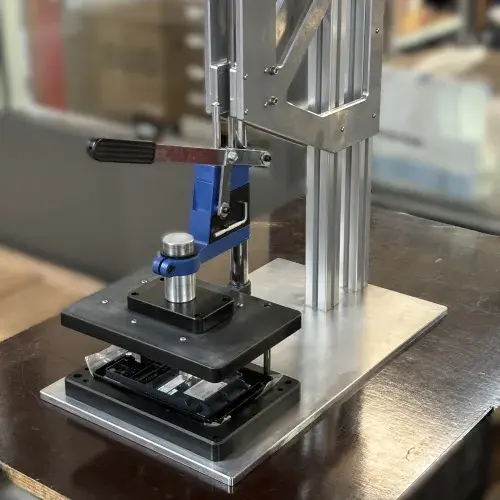

Mechanical Housing Press

In electronics assembly, housings consisting of two shells are often used to protect internal hardware. Consistent and secure assembly is essential, especially for large production volumes. Manual assembly can cause variations in pressure points, damage from incorrect placement, and slower production speeds.

Solution

Contecto developed a press with a custom-made insertion mold designed for precise and efficient assembly of two-piece housings containing internal hardware.

How It Works

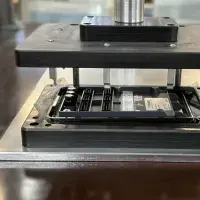

- Insertion Mold with Foam Protection: The insertion mold is equipped with foam that protects the housing from damage. The foam compensates for dimensional tolerances, ensuring stable and secure positioning.

- Fixed Pressing Points: The press applies the upper shell into the lower shell using fixed pressing points, ensuring consistent assembly without misalignments or damage.

- Automated Precision: The standardized operation of the press guarantees that the housing is assembled exactly the same way every time. This reduces human error and significantly accelerates the assembly process.

Result

The implementation of this press with an insertion mold delivered significant benefits:

- Improved Product Quality: Consistent pressure distribution and accurate assembly.

- Increased Production Speed: Fewer manual tasks lead to faster assembly.

- Reduced Defect Rate: Proper assembly prevents defects and damage.

- Efficiency and Consistency: Every housing is assembled precisely according to specifications.

With this custom solution, Contecto leverages smart mechanical engineering to significantly enhance product quality and production speed. An innovative production tool tailored to meet the needs of our clients.